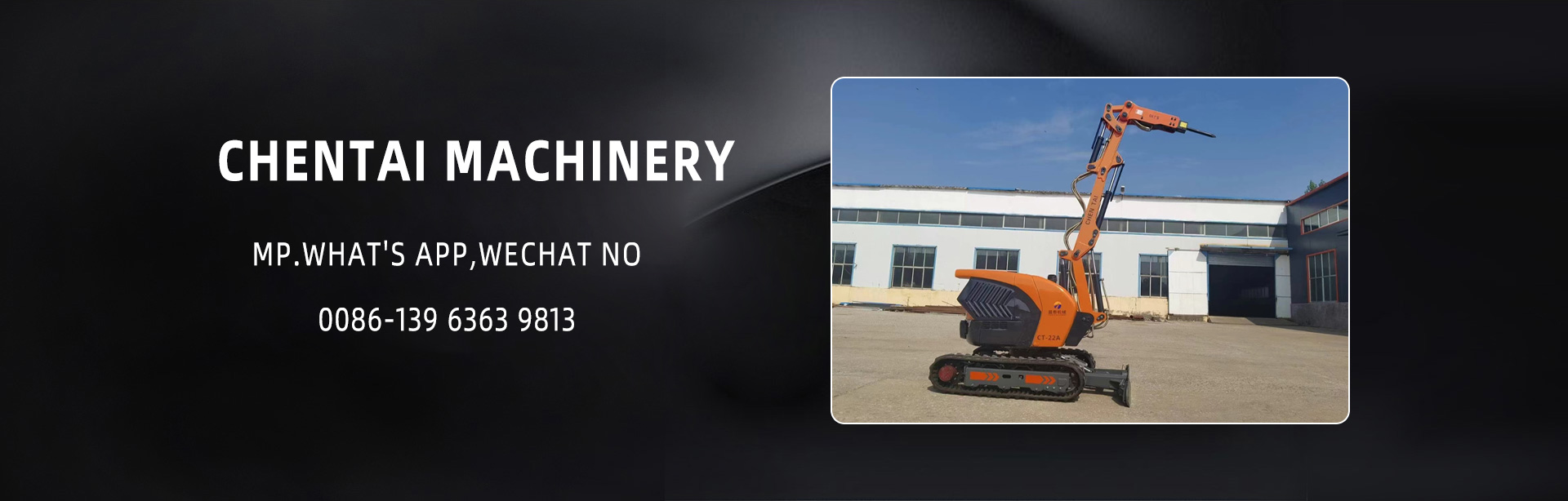

Ladle cleaning machine

Mp.What's app,Wechat No:0086-139 6363 9813

EMAIL:

sales@machinect.com

support@machinect.com

Address: Qingzhou,Weifang City,Shandong,P.R.China.

Postcode:262500

Equipment Overview:

Metal smelting process will produce a large number of scum, if not effective removal of scum, will affect the quality of metal products, the original molten iron slag removal process is generally used dumping slag, or artificial skimming method, whether it is dumped removal or manual cleaning, will cause a certain waste of molten iron and work intensity increase, while there are certain safety risks. This project is designed for the removal of scum in hot metal ladle to improve the quality of steel products.

At present, the traditional slag extraction method mainly used in the iron and steel industry not only has great personal safety risks, but also has great labor intensity, low work efficiency and high loss of hot metal. In order to solve the safety hazards of dredging operation, reduce the labor intensity of dredging and improve the efficiency, our company pioneered the CT series dredging machine in China, which has applied for national patents (ZL201911037730.8), utility model patents (ZL202030238076.4, ZL202030238746.2) and so on. Now the product has been applied to a number of domestic casting enterprises, received the unanimous praise of users, our company developed the CT series slag extraction machine is bound to replace the traditional slag extraction model, which is also the general trend of the development of the steel industry.

2. Main advantages of the equipment

2.1, easy to install, no need to transform the original field equipment, small footprint.

2.2, the core technical requirements: the dredging machine equipment structure is simple, easy to operate; Working radius and working Angle can be adjusted according to site needs; The grasping mechanism greatly reduces the waste of hot metal, realizes remote operation, reduces the work intensity of workers, meets the field use environment, and can work stably for a long time.

2.3 Mode of operation: Continuous operation

The slag dredging machine has a rotating arm beam structure. Park the equipment in a suitable location as required; After the equipment is adjusted to the appropriate skimming Angle through the slewing support on the base, the lifting cylinder, the telescopic cylinder and the slewing support in the supporting base are adjusted again, and the scum is put into the slag hopper.

The equipment has two operating modes: manual operation and wireless remote control. The whole operation process is safe, fast, reliable and stable.

The equipment is easy to install, reasonable layout, safe and reliable operation; Easy to operate, environmental protection and energy saving; Greatly reduce the labor intensity of workers, effectively improve the efficiency of dredging slag, effectively improve the working conditions, improve the safety guarantee.

.jpg)