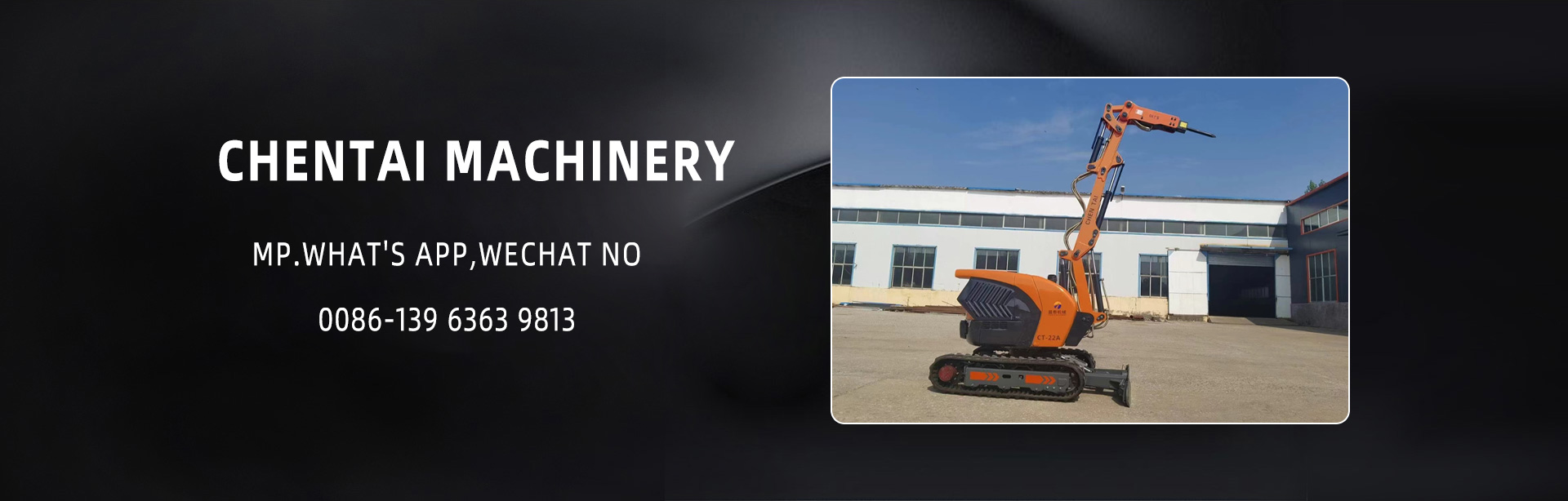

Medium frequency electric furnace dredge machine

Mp.What's app,Wechat No:0086-139 6363 9813

EMAIL:

sales@machinect.com

support@machinect.com

Address: Qingzhou,Weifang City,Shandong,P.R.China.

Postcode:262500

Equipment Overview:

In the process of medium frequency electric furnace melting, a large amount of scum will be produced, which will float and condense on the surface of hot metal. If the scum is not removed, the quality of castings will be seriously affected. At present, the method used in the slag extraction operation in the domestic casting industry is relatively traditional - the slag extraction worker wears protective protective gear and stands at the furnace mouth in a close distance, and uses a long iron fork to pick slag [see Figure 1]. The temperature of molten iron in the furnace can reach more than 1600 degrees Celsius, and the surrounding area of the furnace can also reach hundreds of degrees Celsius, especially in summer, the temperature of the furnace is higher, and the working environment is very bad; Desulphurization slag has strong adhesion, the slag gathered together is very heavy, the labor intensity of manual slagging is very large, and it must be scraped many times to clean the desulphurization slag, the work efficiency is very low; Slagging will adhere to a lot of high-quality hot metal, resulting in a lot of waste of raw materials.

At present, the traditional dreagging method mainly used in the casting industry not only has great personal dangers, but also has very large labor intensity, very low work efficiency and much loss of hot metal. In order to solve the safety hazards of dregs dredging operation, reduce the labor intensity of dregs dredging and improve the efficiency, our company has created a CT series dregs dredging machine in China. We have applied for and obtained national patents (ZL201911307730.8), utility model patents (ZL201921809555.5, ZL201921808523.3), international invention patents (PCT/CN2019/128572), design patents (ZL202030238076.4, ZL202030238746.2) and so on. Now the product has been applied to a number of domestic casting enterprises, received the unanimous praise of users, our company developed the CT series slag extraction machine is bound to replace the traditional slag extraction mode, which is also the trend of the casting industry forward development.

The main body of the equipment adopts the bottom rotating rocker arm structure: 1. The rotation of the main arm is driven by the variable frequency brake motor and can be rotated 360 degrees (controlled by the frequency converter, the rotation speed can be adjusted according to the field situation, and has the safety protection function such as overload and overcurrent, which is far safer than that of the hydraulic motor); 2. The expansion and expansion of the sub-cantilever is controlled by the oil cylinder, which can grab the slag in any part of the furnace chamber; 3. Gripper rotation is controlled by hydraulic motor and can rotate 360 degrees independently; 4. The rise and fall of the gripper and the grasping action of the gripper are controlled by the cylinder; The base, column, cantilever and telescopic arm of the equipment are hard connected to the whole structure, which is safe and reliable.

2, the main advantages of the equipment

2.1, easy to install, no need to transform the original field equipment, small footprint.

2.2, the layout is reasonable, the slag extraction machine can be selected according to the user's site situation, the slag extraction machine is installed in the middle of two electric furnaces, a slag extraction machine can simultaneously take two electric furnaces, saving the user's investment cost; The equipment adopts the bottom rotating rocker arm structure to open the working space around the furnace and reduce the safety risks caused by tripping; Rotary system installed at the bottom of the equipment runs more smoothly; The telescopic arm of the manipulator is fixed, and the gripper structure is independently rotating.

2.3, safe and reliable, the use of ester type flame retardant hydraulic oil as a power source, good flame retardant, to solve the flammable danger of hydraulic oil, hydraulic system pressure is stable, to ensure the stable operation of slag extraction machine.

2.4, easy to operate, the equipment adopts one key automatic slag extraction, manual and remote control three modes of operation, the use of automatic slagging, can automatically complete the slag in the furnace, without manual slagging, reduce manual labor intensity. When the automatic slag extraction fails, it can be freely switched from manual to manual or remote control mode to continue to complete the remaining slag extraction action, which is safer and more reliable than manually standing on the stove side.

2.5, reliable performance, all materials of the equipment are designed and manufactured with high temperature resistance, and electrical components are made of Z&Schneider brand; Hydraulic system adopts Beijing Huade brand; Assembly parts are used in the world reliable brand, or famous domestic brands.

.jpg)